PTFE micropowder: improves the lubricity, wear resistance, non-stickiness and flame retardancy of the base material, and significantly improves the performance of the base material.

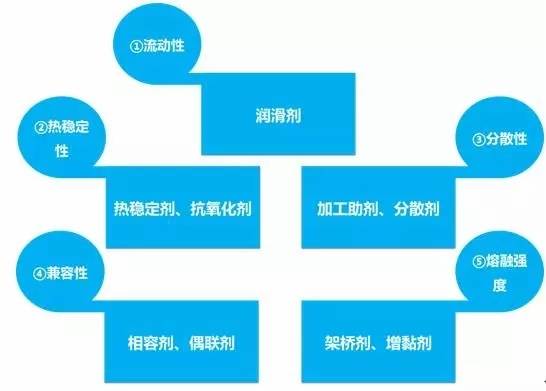

Wax powder: suitable for PE, PP, PS, ABS, PA, PVC, etc., to improve the affinity with inorganic substances and compatibility with polar resins. It has stable chemical properties and good conductivity. It is an ideal choice for color masterbatch production. Effective dispersant. It can effectively improve the brightness of the color of the product.

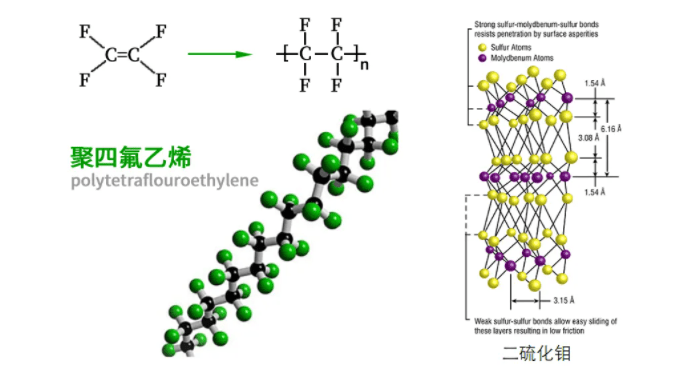

How to improve the wear resistance of engineering plastics? With the addition of PTFE micropowder or layered lubricant such as molybdenum disulfide, due to the reduction of the friction coefficient, the friction force and friction heat will be reduced, and the adhesive wear will be controlled. When the amount of PTFE micropowder added is relatively large, the transfer film between the friction surfaces becomes smoother, showing better wear resistance. The wear mode at this time is mainly the abrasive wear caused by the solid on the polymer opposite the friction pair.

At present, most of the domestic modified wear-resistant engineering plastics are added with molybdenum disulfide. Its wear-resistant mechanism relies on its flaky crystal structure, which can only produce black or gray products. Moreover, in the presence of water, the second The lubricity of molybdenum sulfide will be greatly reduced due to water absorption. The use of PTFE (polytetrafluoroethylene) micropowder can solve this problem.

PTFE micropowder has a low molecular weight, the smallest average molecular particle size can reach about 1.5 microns, and its appearance is white powder. It has all the excellent properties of high molecular weight polytetrafluoroethylene resin. Its outstanding features are: spherical particles, No adhesion or caking, excellent dispersion, small and uniform particle size, large specific surface area, low volume density, high oil absorption value, low viscosity when dispersed in solvent, and can be evenly mixed with other powder and liquid materials mix.

The use of PTFE micropowder can enhance the properties of the host material, such as:

- Wear resistance, friction resistance and scratch resistance;

- 2) Easy decontamination properties;

- 3) Anti-adhesion properties;

- 4) Lubricating properties (used for engineering plastic modification);

- 5) Anti-friction and anti-wear properties .