Product: ADDYSTA Anti-statics 9129

Product: ADDYSTA Anti-statics 9129

Characterization

Characterization

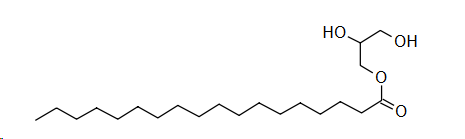

ADDYSTA Anti-statics 9129 is an excellent antistatic agent for polyolefins that provides several beneficial side effects (e. g. lubrication and mold release) and has wide food contact approvals (de- tails upon request).

Structure

Structure

Applications

Applications

Anti-statics 9129 is an internal antistatic agent used in injection molding on a world-wide basis with wide food contact approvals and beneficial side effects. Anti-statics 9129 is used as a process aid in production of expanded polyethylene (EPE) to im- prove the gas exchange (replacement of hydrocarbons -foaming gas- by air). Anti-statics 9129 is recommended in the manufacturing of PP-caps to provide a slip/lubricant ef- fect, in addition to the antistatic effect.

Appearance: Beads

Appearance: Beads

|

Characteristic Index |

Specification |

Unit |

|

Appearance |

Beads |

|

|

Colour |

Off-white |

|

|

Flash point |

> 149 |

°C |

|

Solubility(ies) Water solubility |

insoluble |

|

|

Melting point |

69 |

℃ |

Mode of Action

Mode of Action

Internal antistatic agents act in two ways: building up a conductive path to bring charged particles into contact and as a lubricant or demolding agent in the post-extrusion process. An internal antistatic agent is incorporated into the polymer matrix during the extrusion pro- cess. Upon extrusion, the additive migrates to the surface of the polymer - because of its defined incompatibility with the polymer - where the additive builds up an uniform layer on the polymer’s surface. The hydrophilic end projects out of the polymer, the lipophilic end anchors in the polymer. The protruding hydrophilic end absorbs moisture from the sur- rounding air and builds up a conductive path, reducing the surface resistivity. (This also explains why mainly too high concentrations of antistatic agents will have an influence on printing and sealing properties and why antistatic agents are hygroscopic and have to be handled accordingly)

Features/ Benefits

Features/ Benefits

Using Anti-statics 9129 as antistatic agent reduces dust contamination, affecting both appearance and performance of the end product. Handling problems during transport, storage and packaging are often reduced. In injection molding Anti-statics 9129 reduces the cycle times by providing a mold release effect and improves the surface finishing. In EPE Anti-statics 9129 reduces the friction during the extrusion process, giving an uniform cell size distribution and is improving the gas exchange (facilitating the diffusion of the foaming gas out of the cells and its replacement by air). By increasing the gas exchange rate be- tween the foaming gas and air, Anti-statics 9129 can significantly reduce storage time and cost. Anti-statics 9129 improves the slip characteristics, e. g. of PP-caps, by reducing the forces needed to turn the PP-caps to open or close bottles.

Product Forms

Product Forms

White to slightly yellow microbeads

Guidelines for Use

Guidelines for Use

Polyolefine films (<50 micron):

0.10%-0.25% Polyolefine films (>50 micron):

0.20% - 0.30% Polyolefine injection molding:

0.20% - 0.60% EPE:

1.20% - 1.50%

Physical Properties

Physical Properties

Anti-statics 9129:Free flowing microbeads

Storage

Storage

24 months shelf life (under dry and cool storage conditions)

Typical Sample Size

Typical Sample Size

0.5 kg (quantities for industrial trials at request)

Packaging:

Packaging:

Pallets of 40*25 kg PE-bags (1000 kg)

Big bags of 500 kg